Roll Winding

The science of winding is highly complex. TopWeb has been able to use the latest techniques to capture most important aspects, including air entrapment, gauge-bands, thermal/hygroscopic effects, wrinkles, tin-canning, nip-roller effects etc.

This example gives you a taste of what TopWeb can do.

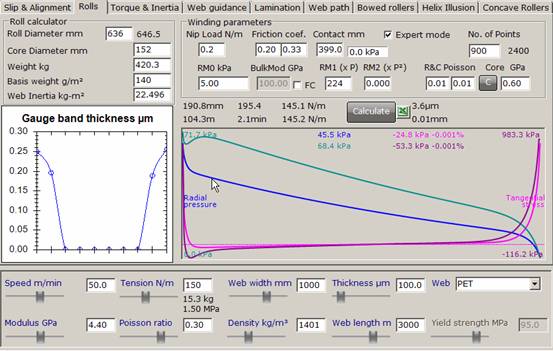

We have a 3000m roll of 100µm PET. It's been wound at 50m/min with a constant tension of 150N/m. There is no nip roll (rider roll). The blue line shows the radial pressure squeezing the roll. It is often a surprise to users that the pressure curve looks like this. It's saying that there is a zone of high pressure near the core then the pressure is nearly constant till the outer wraps when, of course, it falls to zero. This curve is important. If you find defects that appear, say, in the first 1/3 of the roll, it's unlikely that they are due to radial pressure as that pressure would affect 2/3 of the roll.

The curve in magenta shows the tangential stress - i.e. the stretch along the web. At the outer wraps it is identical to the tension you are applying. But throughout most of the roll, the value is negative. In other words, the web is under compression. This is an important danger signal. If it's under compression then it's possible that it can buckle, giving you wrinkles. As it happens, in this example there is no wrinkle or tin-canning warning so you're OK.

There's one surprising fact hidden in the top left corner. TopWeb automatically calculates the roll diameter for you from the length (it will also calculate the length from the roll diameter if you wish). In this case the diameter should be 636mm. Next to that number there's another value, 660.7mm. This is the diameter calculated on the basis of the air being entrained at each turn. This means that you have potentially wound in 23mm of air! Now this is a pessimistic calculation. Air tends to be squeezed out during winding, but it's still a shockingly large number and, unfortunately, not too far from the truth for many such rolls - which is why so many rolls sag on storage.

If you add a very small nip pressure of 0.2N/m then TopWeb calculates that the entrained air is only 9mm, a big reduction in air for a very light rider roller pressure.

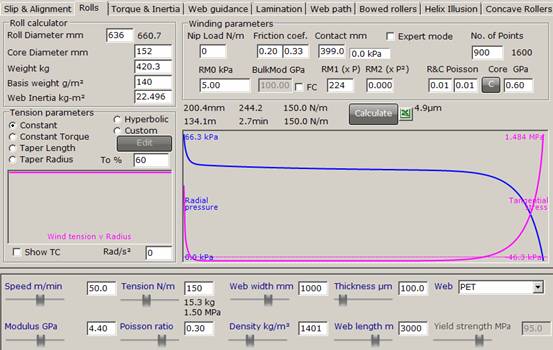

The following includes the effect of the nip load, but has also shown how TopWeb can calculate the effect of a Taper Tension profile, in this case going down to 60% over the length of the roll. Whether the results are what you want, only you can tell.

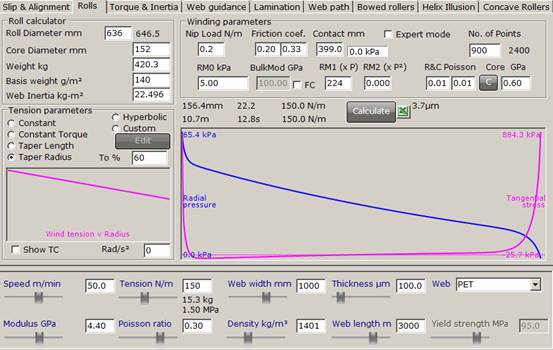

The final example shows the same situation, but this time with 0.3µm gauge bands on the edges of the film. The graph now has multiple lines showing the pressure/stress for a perfect roll and the values at the thickest part of the roll. The mouse is pointing at a region of the roll about 20% of the way through. The average radial pressure is shown at the top as being 45.5kPa and the pressure under the 0.3µm gauge bands is 68.4kPa, a gain of 50%. That's why gauge bands cause us so many problems.