Dip Coating Modeller

Dip coating is a great technique which produces precisely controllable coatings via a very simple process.

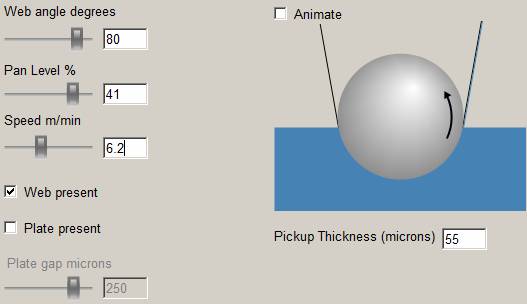

For example, if you have a 2cP liquid and want to produce a 55µm (2.2mil) wet coat weight, TopCoat shows that you simply run the process at 6.2 m/min:

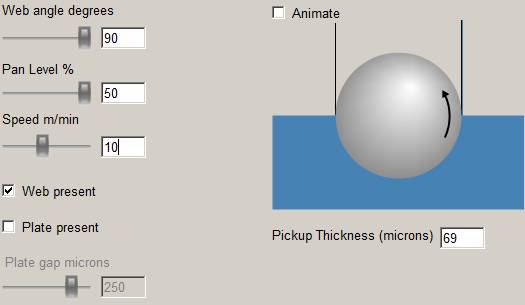

The problem comes when the business wants to cut costs and needs to produce the product at 10m/min.

At this speed your coat thickness is 75µm. What can you do to reduce it? If you increase the web angle/pan level you get down to 69µm as shown. You then try one more setting - you change the viscosity from 2cP to 1.44cP and (not shown on this page) you get your required 55µm. When you mention this to your formulation experts, they tell you that 2cP is their absolute minimum viscosity. What do you do now? Do you tell the business that there's nothing else you can do?

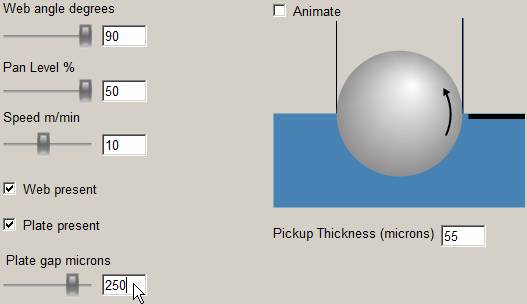

Well, there is one more thing. If you have some good engineers who can place a little plate on the surface of the liquid, with an adjustable gap (a few mm) you will be able to save the day. The subtle surface curvature effects induced by the plate are enough to bring the coat thickness down to 55µm. You've saved the business.