Meter Rod Coating

It's a classic problem. You are using Meter Rod (or Mayer bar) coating and your coating dries before the lines induced by the rod have had time to flow out. Your instinct is to go to a finer rod. But an exploration with TopCoat shows that this could well make matters worse!

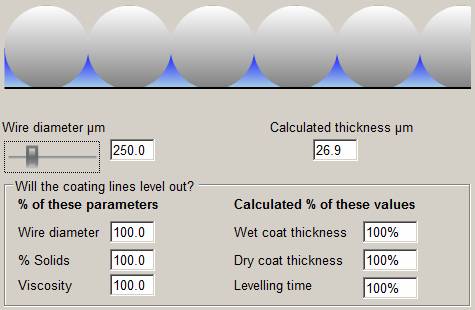

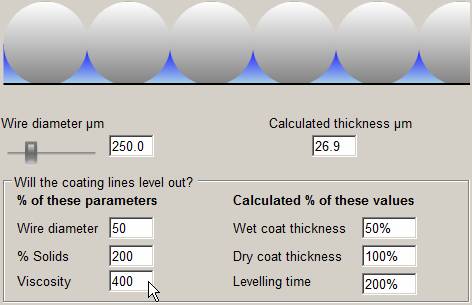

Let's say that you have a 250µm (10mil) rod which produces your desired 27µm wet coating and therefore a certain dry coat thickness defined as 100%. But you have lines. So you halve the wire diameter (the value of 50% in the box) which halves the wet coat thickness (50%), so you double the solids (200%) so you get the same dry coat thickness (100%). But you happen to know that doubling the solids doesn't double the viscosity but quadruples it (400%). It now turns out that the levelling time has doubled - which is exactly the result you didn't want!

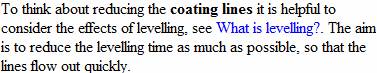

Where do the calculations about levelling time come from? In the text next to the modeller you find the following:

If you click your mouse on the blue hyperlink you are immediately taken to the levelling modeller where everything is explained.