Roll Coating Modellers

There are a number of roll modellers within TopCoat 2 - including rigid, deformable and kiss coat arrangements. In addition there are a number of multi-roll modelers designed to mimic industrial setups very closely. The example below shows a typical 3-roll reverse coating arrangement.

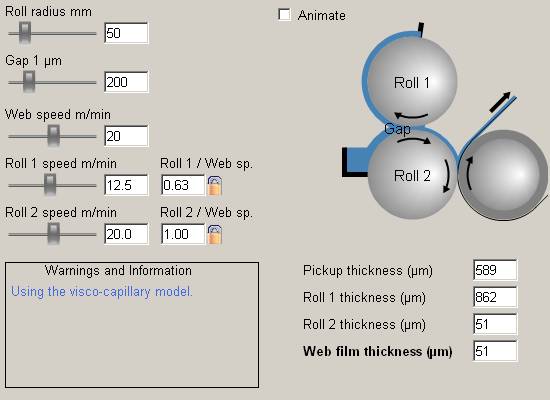

You can first start by modelling your existing process - here for a fluid of viscosity 30cP and surface tension of 30 dynes/cm. The model predicts a wet film thickness of 51 microns (2mil).

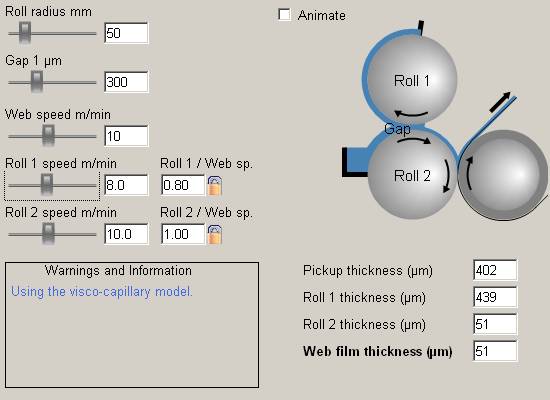

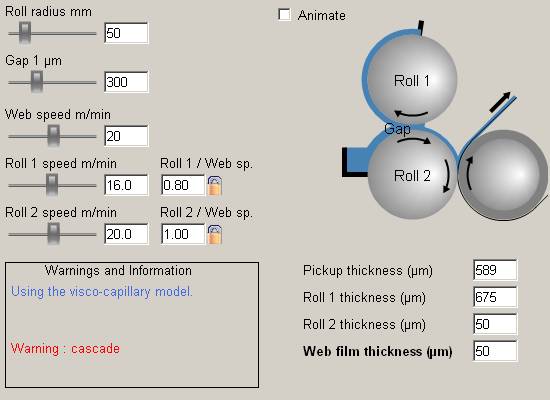

Now imagine you wish to speed up production. What settings do you need to pick to give a similar wet thickness but for a line speed of 20m/min (perhaps you've used the dryer model to set your ovens more efficiently, or invested in extra driers) ? You could do this on plant, but it may take you many hours of wasted production and fiddly measurement to find appropriate settings. It's much easier using TopCoat 2. A first trial may be to increase all speeds by a factor of 2. As shown in the next figure this gives an identical wet film thickness, but that a cascade instability may result, giving an unsatisfactory film quality.

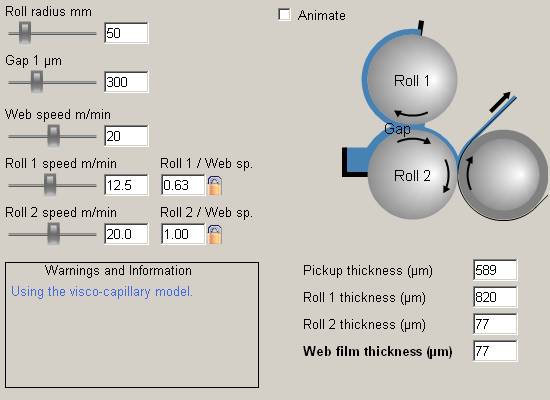

Altering the speed of roll 1 will put the coating back in a safe region away from disturbances, but now you see the film thickness is 77microns (3 mils).

Your final change to the processing parameters is to alter the gap between roll 1 and roll 2. By taking this down to 200 micron (8 mil) its possible to produce a film of desired thickness, still within a safe coating window but at twice the production rate.