Slot Coating Modellers

One of the classic traps with slot coating is to think that because you can produce a thick coating, all you have to do to produce a thin coating is reduce your flow rate and maybe move the slot a bit closer to the web.

With TopCoat it is very easy to see why thin coatings are much more difficult.

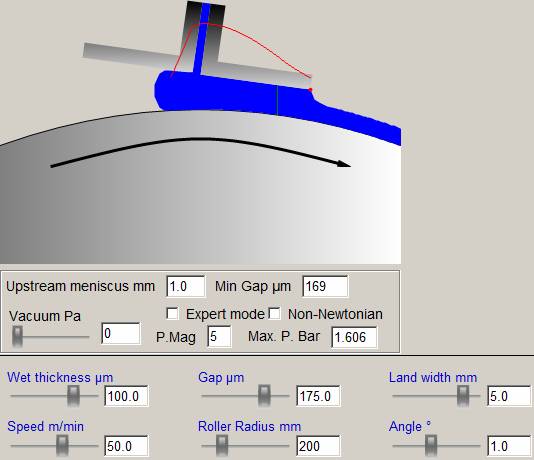

Here is a thick (100µm, 4mil) coating:

You can use a large coating gap of 175µm (7mil) and when you change the gap you find that you have no problems even if the gap varies by ±25µm (1mil).

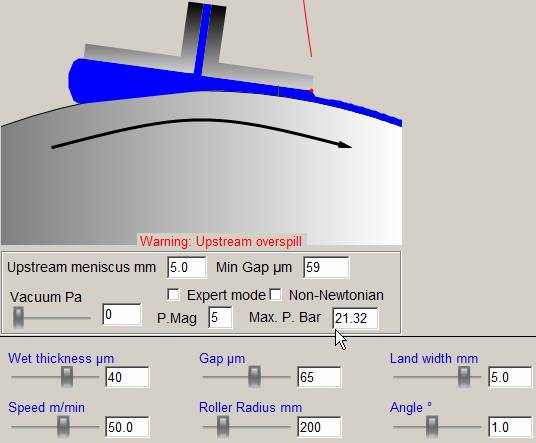

But when you shift to 40µm (1.6mil) you first need a smaller gap of 75µm (3mil) and you find that at 80µm you have an unstable inflow:

and at 65µm you have upstream overspill and also a massive 21.3 bar back pressure.

In other words, a "simple" change from 100µm to 40µm means that what was an easy coating with a wide window has become a high-pressure event with a very tight demand on the accuracy of your slot-to-base gap.

What can you do if you really need to coat 40µm? TopCoat makes it easy for you to change all the parameters (land width, angle, viscosity etc. etc.) so you can explore the tradeoffs and reach your technical decision. In this particular example, going to a narrower land width would be the choice of most users.